Polylit panels are made with Unsaturated Polyester UV Stabilized, specifically designed to fit various light transmitting applications such as post frame buildings, pre-engineered metal buildings and greenhouses. Polylit Panels are available in a variety of popular shapes which makes them a perfect choice where natural lighting is preferred.

CUTTING

Panels can be cut using power or hand saws. Saw blades should be fine-toothed carbide tipped or a safety fabric reinforced abrasive disc. Face shields and appropriate safety equipment should be worn by all operators. Some typical installation details are shown below.

DRILLING

All panels should be pre-drilled not less than 1-1/2″ from panel end, and the holes drilled a minimum of 1/16″ larger than the fastener diameter. Panels can be drilled singly or several at a time.

FASTENERS

When possible fastener should be installed at high points of the corrugation, with spacing of 6″ to 8″ on center and at end panel ends 6” to 8” on center. Fasteners should be installed 12″ to 16″ on center for intermediate purlins and siding applications.

SEALING

Seal end and side laps with a flexible non-hardening, UV stabilized butyl caulk.

INSTALLATION

Under no circumstances should panels be allowed to support undistributed loads such as the weight of a human body. Use only approved roof ladders for installation.

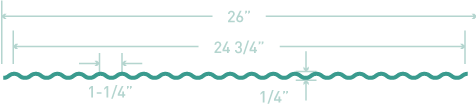

Width – 26″ Length – 24-3/8″

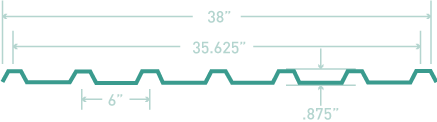

Width – 38″

Coverage – 35-5/8″

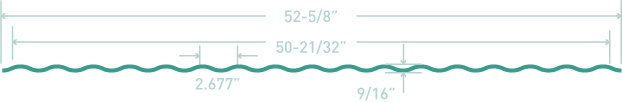

Width – 52-5/8″, 51-1/2, 34″, 26″

Coverage – 50-21/32″, 48″ 32″, 24″

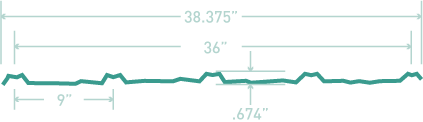

Width – 38-3/8″ Coverage – 36″

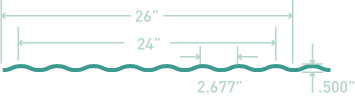

Width – 26″ Coverage – 24″

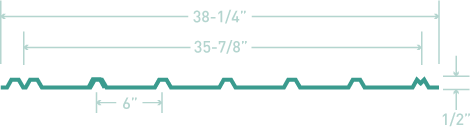

Width – 38-1/4″ Coverage – 35-7/8″

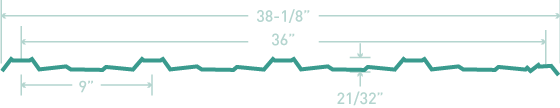

Width – 38-1/8″ Coverage – 36″

Width – 38-1/4″ Coverage – 36″

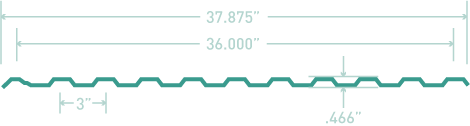

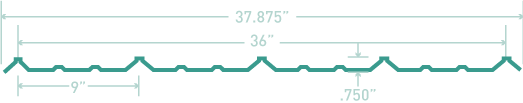

Width – 37-7/8″ Coverage – 36″

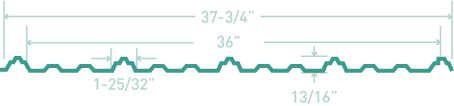

Width – 37-3/4″

Coverage – 35-7/8″

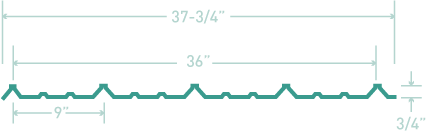

Width – 37-3/4″ Coverage – 36″

Width – 26-1/4″

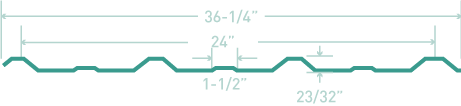

Coverage – 24″

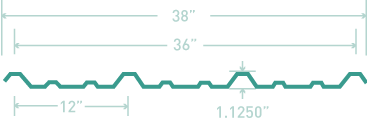

Width – 38″ Coverage – 36″

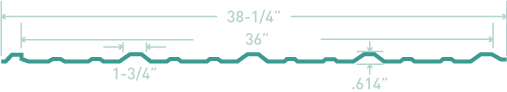

Width – 38-1/4″ Coverage – 36″

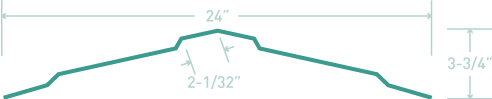

Width – 24″

Width – 48″ Coverage – 50′ Rolls

Polyester Panel