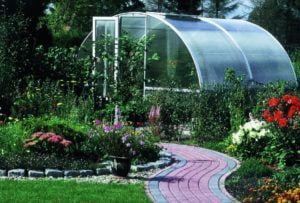

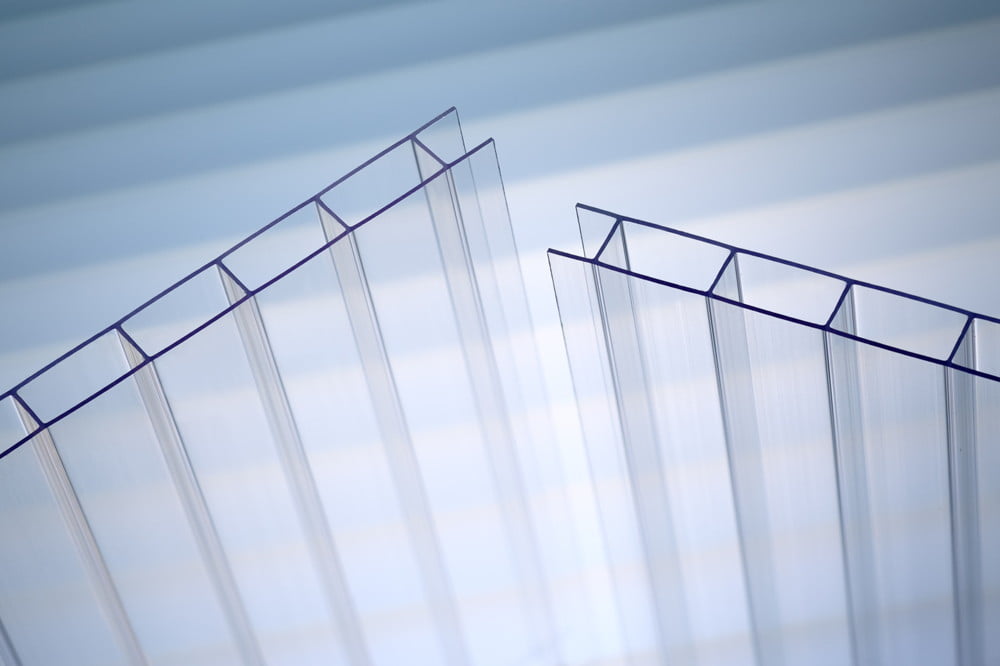

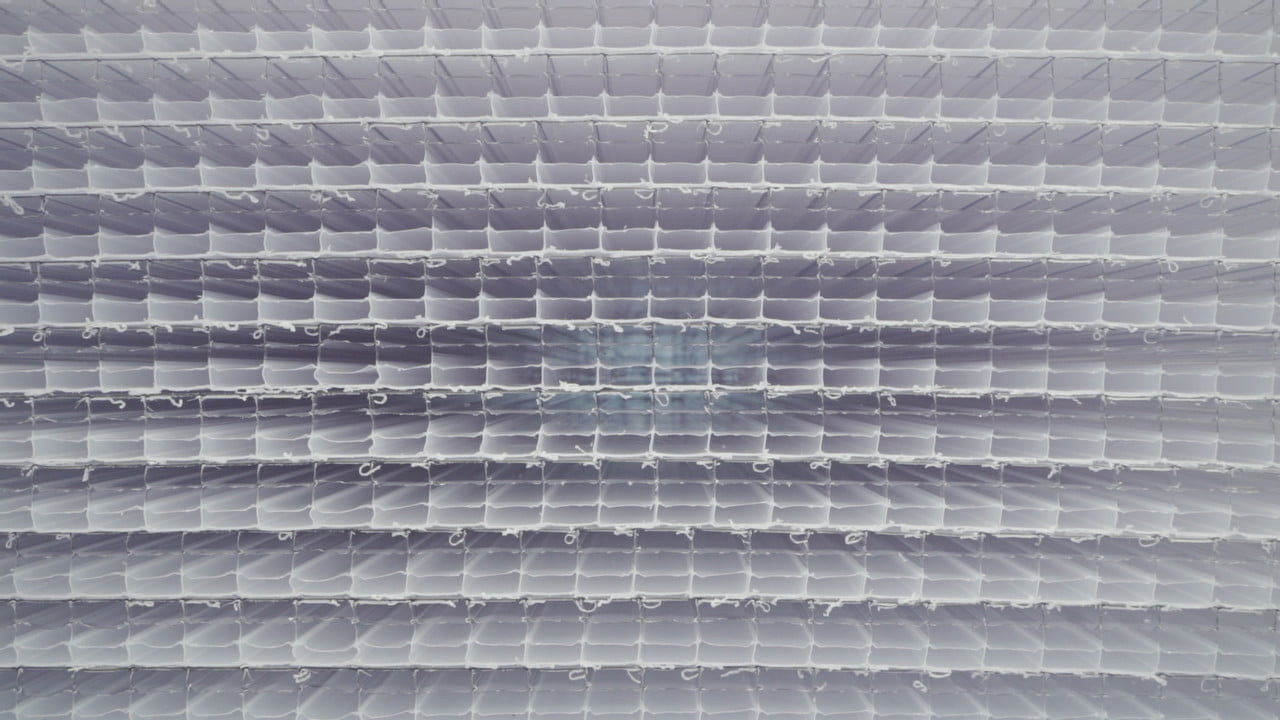

Polycarbonate Multiwall is a high performance roofing sheet which has been designed for industrial, commercial, architectural and domestic applications where insulating glazing is required.

It offers a 10 year non-prorated warranty against loss of light transmission and yellowing in accordance to ASTM 0-1003, thanks to the co-extruded UV protected PC layer fused to the PC substrate of the sheet.

| Physical Properties | |||||||

|---|---|---|---|---|---|---|---|

| Physical specification | |||||||

| Sheet Thickness | 4mm | 6mm | 8mm | 8mm | 10mm | 10mm | 16mm |

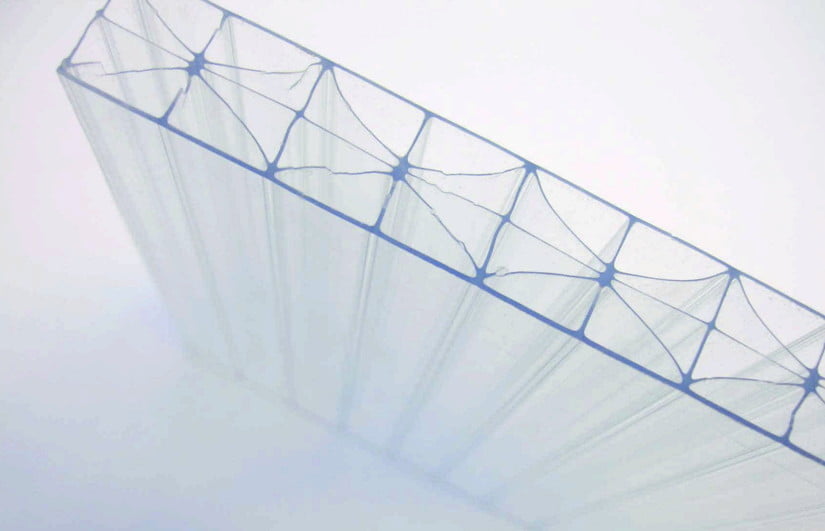

| Structure | Twin Wall | Twin Wall | Twin Wall | Triple Wall | Twin Wall | Triple Wall | Triple Wall X-Structure |

| Weight (lb/ft2) | 0.16 | 0.26 | 0.3 | 0.3 | 0.34 | 0.34 | 0.5 |

| Weight (g/m2) | 800 | 1300 | 1500 | 1500 | 1700 | 1700 | 2500 |

| Light Transmission {%) Clear | 82 | 80 | 80 | 80 | 80 | 80 | 59 |

| Light Transmission {%) Bronze | 52 | 50 | 50 | 50 | 46 | 46 | 31 |

| Light Transmission (%) Opal | 61 | 55 | 54 | 54 | 54 | 54 | 54 |

| Light Transmission (%) White | 37 | 23 | 19 | 19 | 15 | 15 | 4 |

| Width (in.) | 47.25″, 48″, 71.25″, 72″ and 82.67″ | ||||||

| Length (ft.) | 8′, 12′, 18, 36’up to 48′ | ||||||

| Gauges | 4mm(3/16″), 6mm(1/4″), 8mm(5/16″), 10mm(3/8″), 16mm(5/8″) | ||||||

| Basic colors | Clear / White / Smoke | ||||||

| Selection | ||||||||

|---|---|---|---|---|---|---|---|---|

| Thickness | Weight (lb/ft2) | Weight (g/m2) | Light transmission crystal | Sound reduction index | Cold forming radius | Standard colors | ||

Twin Wall (2W) |  | 4 mm | 0.16 | 800 | 82% | N/A | 29.5 in | Crystal White Bronze Green Blue Smoke Grey Pearlescent Grey Opaline Red Yellow |

| 6 mm | 0.26 | 1300 | 80% | 10 | 39.4 in | |||

| 8 mm | 0.30 | 1500 | 80% | N/A | 49.2 in | |||

| 10 mm | 0.34 | 1700 | 80% | 16 | 59.1 in | |||

Triple Wall (3W) |  | 8 mm | 0.30 | 1500 | 74% | 14 | 51.2 in | |

| 10 mm | 0.34 | 1700 | 80% | N/A | N/A | |||

Triple Wall X-Structure (3WX/16) |  | 16 mm | 0.50 | 2500 | 59% | 21 | 94.5 in | |

| Technical Data | |||||||

|---|---|---|---|---|---|---|---|

| Property/ Thickness | Unit | 4mm | 6mm | 8mm | 8mm | 10mm | 16mm |

| Structure | Twin Wall | Twin Wall | Twin Wall | Triple Wall | Twin Wall | Triple Wall X-Structure | |

| Thermal Insulation BTU/hr-ft2ºF (ASTM C976/90) | U-Value R- Value | 0.72 | 0.62 1.6 | 0.60 1.7 | 0.60 6.47 | 0.56 1.9 | 0.42 2.4 |

| Cold Forming Radius (Minimum permissible) | Inch | 29.5 | 39.4 | 49.2 | 49.2 | 59.1 | 94.5 |

| Heat expansion coefficient | Inch/ft °F | 4×10-4 | 4×10-4 | 4×10-4 | 4×10-4 | 4×10-4 | 4×10-4 |

| Max. permanent service temperature w/o load | °F | 250 | 250 | 250 | 250 | 250 | 250 |

| Possible expansion due to Heat and Moisture | Inch/ Inch | 0.003 | 0.003 | 0.003 | 0.003 | 0.003 | 0.003 |

| Weighted sound reduction index | dB | N/A | 10 | N/A | N/A | 16 | 21 |

* Based on ISO 10077-2

Load Deflection

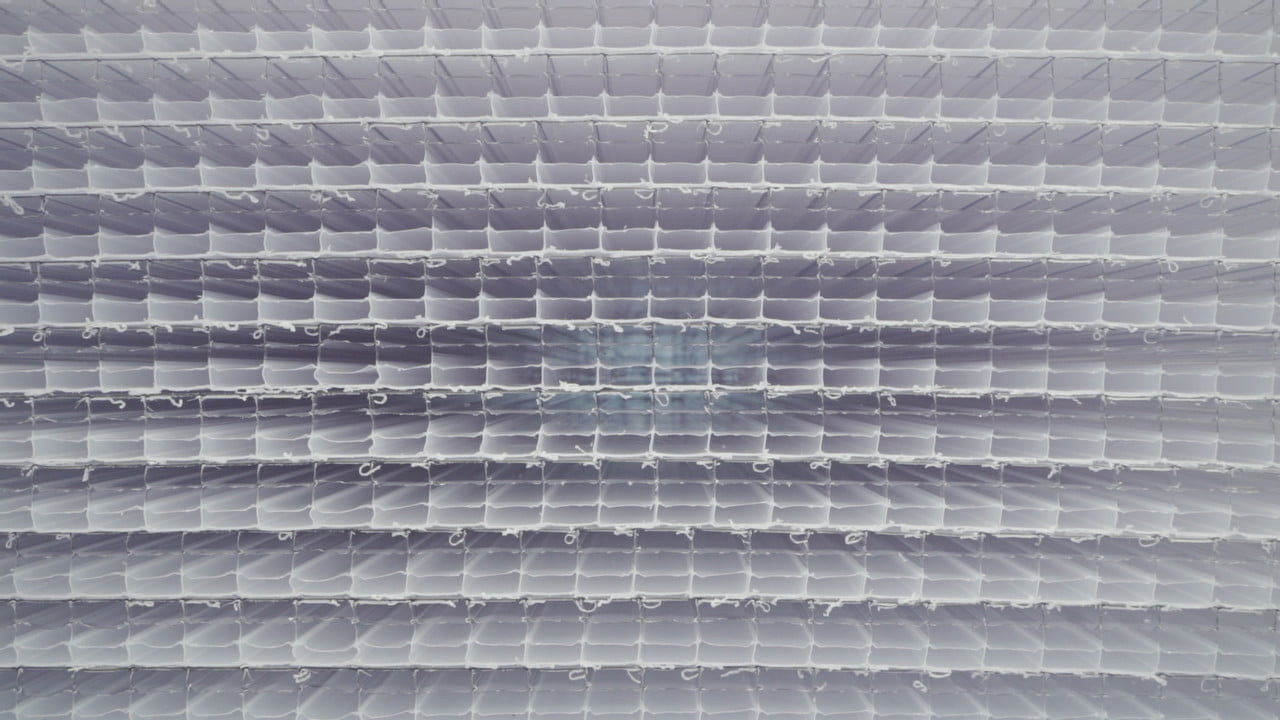

When Polycarbonate twin wall sheet is used as a structural element in roofs and walls, the forces applied by wind and snow loads must be absorbed by a suitable structure. Also, adequate locking devices must be used to protect the whole structure (PC sheet and metal or wood structure) against wind suction.

The anticipated structural load values are specified in local building regulations. The total applicable load deflects the sheet. For safety and aesthetic reasons, the maximum bend should be limited to 5% of the dimensions of the shorter side of the sheet.

| For a 4′ wide sheet | ||||

|---|---|---|---|---|

| Maximum Purlin Spacing (inches) sheet deflection -1″ | ||||

| Load (lb-f/ft2) | 15 | 30 | 45 | 60 |

| 6mm | 31″ | 24″ | 12″ | – |

| 8mm | 38″ | 28″ | 18″ | 10″ |

| 10mm | 45″ | 34″ | 28″ | 24″ |

| 16mm | 75″ | 43″ | 36″ | 30″ |

| For a 6′ wide sheet | ||||

|---|---|---|---|---|

| Maximum Purlin Spacing (inches) Sheet Deflection -1″ | ||||

| Load (lb-f/ft2) | 15 | 30 | 45 | 60 |

| 6mm | 25″ | 9″ | – | – |

| 8mm | 36″ | 26″ | 12″ | – |

| 10mm | 44″ | 33″ | 27″ | 20″ |

| 16mm | 60″ | 40″ | 36″ | 30″ |

Heat Expansion

Glasteel’s PC sheet has a higher heat expansion coefficient than standard construction materials such as glass, steel and aluminum. Specific clearance between the sheet and the structural frame has to be calculated in order to ensure proper installation.

| Material | Heat Expansion Coefficient (inch/ftºF) | |||

|---|---|---|---|---|

| Makrolon® | 4 x 10-4 | |||

| Glass | 5 x 10-5 | |||

| Steel | 8 x 10-5 | |||

| Aluminum | 1.6 x 10-4 | |||

Fire Behavior

Glasteel’s Macrolux Multiwall sheet is produced using high-quality polycarbonate resin made by Bayer. It does not burn easily and has been defined as a self-extinguishable material by international standards in different countries.

| Fire Behavior | ||||

|---|---|---|---|---|

| ASTM | CLASSIFICATK | |||

| ASTM E84-01 | ClassA (NFPA); Class (UBC) | |||

| ASTM D635-74 | Class CC1 | |||

| ASTM D2843-93 | Low Smoke Density (UBC standard No. 26-5) | |||

| ASTM D1929-68 | Self Ignition Temperature greater than 650ºCF | |||

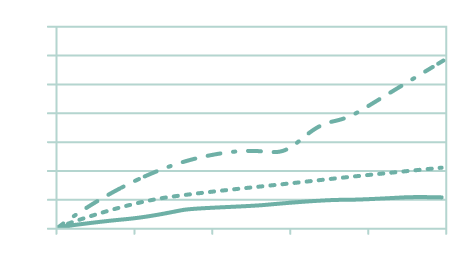

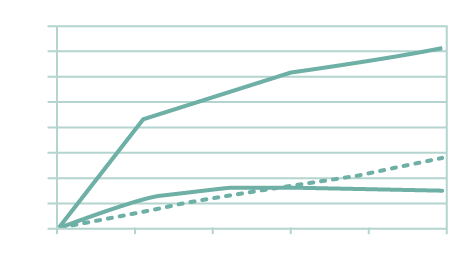

Change in the light transmission of PC sheet in time

Change in the yellowness index of PC sheet in time

MSDS 2017

Format: pdf

Features advanced solar control properties, improved room comfort and high light transmission. (55.4 degrees Fahrenheit less inside temperature vs standard multiwall polycarbonate panel).

Features a special water dispensing layer that prevents drop formation in humid conditions typically found in greenhouses.

Offers an optimal combination of high light transmission from natural sunlight that enhances the photosynthesis process, and reduced temperatures by reflecting IR rays that cause extreme heat.

Two sided UV protection for superior resistance which helps maintain long-term high light transmission and provides cutting and installation advantages.

Features a ground glass appearance, providing greater light diffusion.

| Accessories | |||||

|---|---|---|---|---|---|

| Type | Accessory Sample | Presentation | Color | Application | Length or amount |

| Standard U-Profile |  | For 4 & 6 mm, for 8 & 10 mm | Clear White Bronze | To cover the cells and prevent leaks | 10´ ( 3,66 mts), in pack of 10 pieces |

| Standard H-Profile |  | For 4 & 6 mm, For 8 & 10 mm | Clear White Bronze | To join multiwall panels | 24´ ( 7,32 mts), in pack of 10 pieces |

| H profile molding Clamp |  | For 4 & 6 mm, for 8 & 10 mm | Clear | To join multiwall panels | 24´ ( 7,32 mts), in pack of 10 pieces |

| Vented Tape |  | 16´, 147 ´(5 ml, 45 ml) | Aluminum | To seal allowing breathing the material | min. 10 pieces |

| Aluminum tape |  | 16´, 147 ´(5 ml, 45 ml) | Aluminum | To seal | min. 10 pieces |

| Buttons |  | For 4 & 6 mm, For 8 & 10 mm | White | When perforation is absolutely necessary | min. 10 pieces |

It is recommended to use 100% alcoholic based silicone perimeter sealant such as DOW Corning-791 or equivalent

Multiwall Panels